Job Shop

Job-Shop Production can be looked at as a special case of the I-Flow.

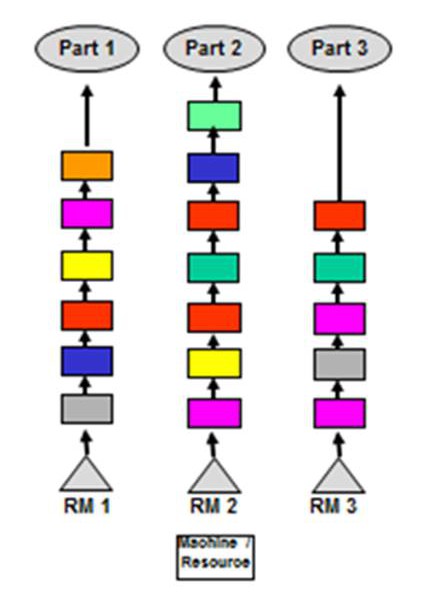

It is usually a machine shop that is producing parts for assembly as an internal supplier, or as outsourcing services for assembly plants. The parts are produced according to their own routings (process sheets) and they move around from one machine to another.

There is no predetermined flow, therefore, the flow sometimes looks like a “spaghetti diagram”. Usually the routing has one material and ends up with a single part – hence there is no problem of stealing or missing components.

The typical problems are associated with lack of capacity and unavailability of machines and resources when needed.

Source: Oded Cohen and Jelena Fedurko, Theory of Constraints Fundamentals, 2012