THEORY OF CONSTRAINTS

Theory of Constraints (TOC) is a managerial approach developed by Dr. Eli Goldratt to allow businesses and organizations to achieve breakthrough improvements in their performance.

TOC provides a set of holistic processes and rules, all based on a systems approach, that exploits the inherent simplicity within complex systems through focusing on the few “leverage points” – constraints – as a way to synchronize the parts to achieve ongoing improvement in the performance of the system as a whole.

TOC is driven from the concept of inherent simplicity and states that everything within a system is connected by cause and effect relationships – there are no complex systems in reality.

TOC Knowledge covers the following areas of management:

- Operation (production) management – Make to Order (MTO) environment and Make to Availability (MTA)

- Project Management – CCPM – Critical Chain Project Management

- Distribution & Supply Chain Management – DTA – Distribute to Availability

- Finance & Measurements – Throughput Accounting

- Sales Management

- Marketing – Developing Market Offers

- Managing People – Management Tools (MT)

- Strategy & Tactics – Developing a companywide improvement plan

Proven TOC Success in Industries:

- Manufacturing

- Distribution

- Financial Services

- Health

- Defense

- Government

- Education

- Social Services

TOC IS BASED ON 3 BASIC ASSUMPTIONS

Basic Assumption 1:

Everything within a system is connected by cause and effect relationships. Identification of the causes leads us to converge onto an apparent core problem/contradiction/conflict.

Basic Assumption 2:

All contradictions can be resolved without compromise – our level of understanding and our assumptions hold the contradiction in place. A compromise is not usually a win-win solution.

Basic Assumption 3:

There is no resistance to improvement – people do not embrace change because we have not brought them to see the win for them.

What is unique about TOC? Summary of the Basic Assumptions

- Search for a logical reasoning

The use of Cause & Effect relationships to structure our thinking, record our analysis and understand the suggested solution for any problem (based on Convergence) - Resolve conflicts

A strong belief that there should be no conceptual conflict within our reality – hence – striving to find a win-win solution to any perceived “no solution situation” (Local & Global) - Seek for collaboration and contribution

The use of TOC logical tools logic to communicate to ourselves and thereafter to the team with the view of working together to achieve the desired improvement (based on Respect)

TOC – SYSTEMS AND SYSTEM THINKING

In order to understand the system, under TOC we focus on:

- The “goal” of the system or process

- The measurement of the achievement of the “goal”

- The flow of the system (If there is a flow there are dependencies. If you have dependencies – you have the constraint.)

- The blocking factors to the flow

- The conflicts related to the constraint

- Managing the flow through the constraints

What prevents us from achieving the goal?

CONSTRAINTS – factors or elements that determine how much the system can accomplish.

Main types of constraints of a commercial system:

Capacity Constraint – a resource which cannot provide timely capacity the systems demands for it.

Market Constraint – the amount of customers orders is not sufficient to sustain the required growth of the system.

Time Constraint – The response time of the system to the requirement of the market is too long to the extent that it jeopardizes the system’s ability to meet its current commitment to its customers as well as the ability of winning new business.

THE FIVE FOCUSING STEPS OF TOC

- Identify (choose) the system’s constraint.

- Decide how to exploit the system’s constraint.

- Subordinate everything else to the above decision.

- Elevate the system’s constraint.

- If the constraint is broken go back to step one but do not allow Inertia to cause the system’s constraint.

MANAGING SYSTEMS:

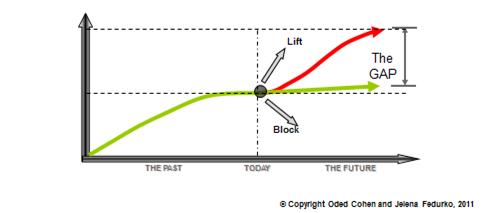

The Leader of a system sees their role as to ever improve the performance of the system under their responsibility.

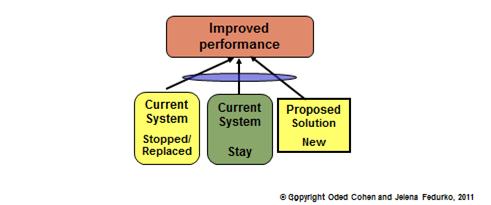

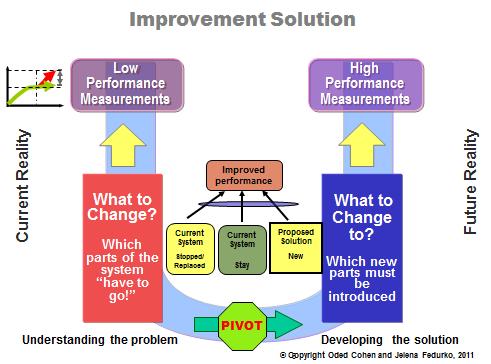

Improved performance is a result of implementing a new idea (“solution”) onto the existing system.

The manager who introduces the solution needs to know:

- Which parts of the system are “erroneous” and have to be replaced

- The new parts must be introduced to replace the erroneous parts

- All the other parts of the system stay as they are!

Managers need a systematic approach to develop plans for the pursuit of a significant improvement of their systems. This systemic approach is about finding answers to the four questions of system improvement.

- WHAT to change?

Pinpoint the core problem - WHAT to change TO

Construct simple practical solutions - HOW to cause the change?

Induce the proper people to make the change (to invent such solutions) - What creates the process of ongoing improvement (POOGI)?

Create a mechanism to determine what to improve next

TOC enhances the ability of managers to develop or construct solutions for improving the performance of their systems. At the same time – TOC also enhances the ability to communicate the solution to the proper people that their support and collaborations is necessary for implementing the solution.

Years of experience in implementing changes for improvements have taught us that what is perceived to be “Resistance to Change” stems, in most of the cases, from disagreement with the initiator of the change. We have also learned that the disagreement is structured logically. There are potential six layers of resistance to change:

- Disagreement on what the problem is

- Disagreement with the direction of solutions

- Disagreement that the solution will bring the desired benefits

At this stage people tend to agree that conceptually there is a solution, but… (Yes, BUT…)

- Fear that the solution will result in negative consequences (risks)

- Obstacles to implementation seem to be impossible to overcome

The above Five layers can be addressed logically by using the TOC Thinking Process (TP).

- Say “Yes” and do nothing

The six layer demands Leadership and people skills to draft people to support and contribute to the successful implementation of the solution.