7. Applying manufacturing flow theory to construction management (Stratton, Koskela, AlSehaimi and Koskenvesa)

We are continuing to publish a new book Theory of Constrains in Practice from the TOC Strategic Solutions Library. It is a collection of cases and articles by TOC experts and practitioners from all around the world sharing their knowledge and experience gained in TOC implementations.

This chapter belongs to a collection of vintage articles written by leading TOC practitioners. It was first published in 2010.

Stratton et al., 2010. Applying Manufacturing Flow Theory to Construction Management. Proceedings of the Interantional European Operations Management Association Conference Porto, Portugal.

The authors:

Dr. Roy Stratton is Associate Professor on Operations and Supply chain Management at Nottingham Trent University in the UK. His research into managing flow in complex environments extends across healthcare and construction environments. He runs an MSc in Theory of Constraints.

Nottingham Trent University, Nottingham, NG1 4BU, UK

Professor Lauri Koskela is Professor of Construction and Project Management at the University of Huddersfield in England. He is a founding member of the International Group for Lean Construction, and has contributed to the theory of Lean Construction.

Professor Lauri Koskela is Professor of Construction and Project Management at the University of Huddersfield in England. He is a founding member of the International Group for Lean Construction, and has contributed to the theory of Lean Construction.

The University of Salford, Salford, M5 4WT, UK

Dr. Abdullah Alsehaimi is a head of civil engineering department, college of engineering in Yanbu, Taibah University, Saudi Arabia. He is also the general supervisor of the medical city projects – a teaching hospital (400 bed) and medical colleges which all under construction.

Dr. Abdullah Alsehaimi is a head of civil engineering department, college of engineering in Yanbu, Taibah University, Saudi Arabia. He is also the general supervisor of the medical city projects – a teaching hospital (400 bed) and medical colleges which all under construction.

A.O.Alsehaimi@pgr.salford.ac.uk

The University of Salford, Salford, M5 4WT, UK

Anssi Koskenvesa is a Finnish entrepreneur, trainer and researcher in the field of construction production and production planning. He has been involved in Lean Construction since 1993 and a founding member of the International Group for Lean Construction.

Tampere University of Technology, Tampere, Finland

Abstract

Both lean and Theory of Constraints (TOC) applications are now commonly reporting success in the application of flow concepts to construction management, namely, lean construction and Critical Chain Project Management (CCPM). Both approaches are concerned with improved flow through synchronization and reduced waste, but the means by which this is achieved are distinctly different. This paper reports on the conceptual similarities and distinctions of CCPM and lean construction based on secondary sources together with separate case and action research studies previously published by the authors.

Keywords: Critical Chain, Lean Construction, Last Planner

Introduction

Theory in operations management has undergone significant change in the past 40 years with a shift from an economic cost-based view to one emphasizing flow and the drive to continually eliminate waste and manage variability. The emphasis on variation and waste reduction are most notably associated with Deming (1982), Ohno (1988) and Womack et al. (1990) and now the term Lean. Whereas the strategic management of variation and uncertainty emerged with Skinner (1974), Hill (1985) and more recently Goldratt (1990) and Hopp and Spearman (2000) who more explicitly use the concept of variability buffering.

This shift in manufacturing thinking has not been so evident within the largely separate operations field of project management, where the underlying theoretical basis for project planning and control remains largely cost focused and has not significantly changed in over 50 years. For example, it has been long acknowledged that the planning and control tools, such as network planning and scheduling, do not effectively supported project management generally, and construction management in particular, with Fondahl’s (1980) experience remaining common today.

‘All too often, however, only the original plan and scheduling data are ever produced. They continue to cover the office wall long after they are obsolete and bear little resemblance to the current progress of the job.’

(Fondahl, 1980).

This paper attempts to bring together two independent developments in project/construction management that address this issue by translating manufacturing flow concepts into the field of construction management, namely Lean Construction (LC) and Critical Chain Project Management (CCPM).

- The International Group for Lean Construction (IGLC) was formed in 1993 and although Lean Construction embodied the flow and continuous improvement principles of lean manufacturing, few of the associated manufacturing tools were applicable. Hence, practical approaches emerged and today best practice is closely associated with Last Planner (Ballard, 1994) which will form the basis of this paper’s interpretation of lean construction (Koskela and Ballard, 2006).

- CCPM (Goldratt, 1997) is a natural development of the Theory of Constraints (TOC) approach to managing flow in manufacturing, entitled Drum, Buffer, Rope (DBR) (Goldratt, 1990). CCPM, like DBR, utilizes time buffers to synchronise uncertain activities and is centred on flow rather than cost control. Over the years this approach has been refined and this paper’s interpretation of CCPM is based on the CCPM Strategy and Tactics tree (Goldratt, 2007) developed to support the implementation process.

Specific questions to be addressed in this paper are:

- How and why do the conceptual approaches work?

- What evidence is there to support the claimed benefits?

- How and why do these two approaches theoretically relate?

- What are the wider implications for construction and project management?

In addressing these questions the authors have drawn on both secondary sources and their primary case and action research knowledge of such implementations (AlSehaimi et al., 2009; Koskenvesa and Koskela, 2005; Stratton, 2009).

How and why do the conceptual approaches work?

The main features of LP and CCPM are outlined below with a theoretical explanation.

Last Planner

The Last Planner system (LPS) was developed piecemeal, in response to the discovery of additional functions needed in order to manage the problem of work flow variability. This can be classified as follows: Ballard (2000)

- Firstly, by incorporating ‘look ahead planning’ and the ‘make-ready’ process, construction managers are able to ensure that materials, information and equipment are available.

- Secondly, it allows for filtered planned activities through the weekly work planning procedure, thus making sure that the preceding activities have been completed.

- Thirdly, it secures the voluntary and reliable commitment of the workforce by the leaders of the work teams involved.

Moreover the important role of the Last Planner tool is to replace optimistic planning with realistic planning by evaluating the performance of workers based on their ability to reliably achieve their commitments.

The concept of the Last Planner System has five main integrated elements (Ballard and Howell, 2003; Mossman, 2007), namely, master planning, phase planning, look ahead planning, weekly work planning and percent plan complete.

- Master Plan is a general plan that identifies all the work packages for the whole project showing the main activities, their duration and sequence. The aim is to bring all the major actors together early in the process where assumptions are tested and best practice agreed on.

- Phase Planning is about dividing the master plan into various phases to develop more detailed work plans and provide goals that can be considered targets to the project team. Phase planning similarly involves representatives of all organizations in order to develop a more detailed work plan for the different parties (contractor, subs, client, consultant, suppliers, etc) involved in the phase.

- Look Ahead Planning is about making tasks ready so that they can be done when the right time comes. The objectives of look-ahead are to reduce uncertainty, identify and eliminate constraints to achieving the project objectives in the look-ahead period, which typically varies from 4-8 weeks. ‘Making ready’ ensures that tasks are ready for production when required, thereby reducing waste in time, materials and equipment.

- Weekly Work Plan (WWP) is the collaborative agreement over the production tasks to be completed within the next week. WWP is produced based on look ahead planning where efforts should be made to defined what will be done given the resources available. The purpose of the weekly meeting is to communicate progress, plan the following week and make ready for the future. This helps to explore any inter-dependencies between resources, access, and equipment. The WWP meeting covers the weekly plans, safety issue, quality issue, resources, construction methods, and any problems that occur in the field.

- Percent Plan Completed (PPC) & analysis of reasons for non-completed tasks. This is about improving the project planning by continual assessment and learning from failure. PPC is a measure of the proportion of promises made that are delivered on time. Having measured the PPC it is then necessary to identify reasons for non-completion, and tracing reasons back to root causes that can be eliminated to prevent repetitions. Additionally, over time PPC statistics show where more attention should be paid to yield better results. This in turn can assist improving the learning process over the project period and over projects.

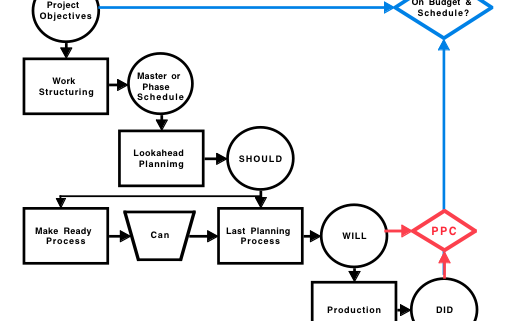

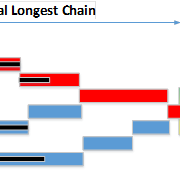

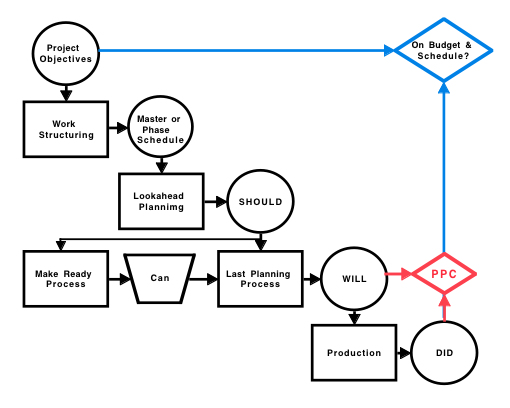

Figure 1 The Last Planner System (LCI, 2001)

In the Last Planner System the sequences of implementation of the above mentioned elements set up an efficient planning framework through a pull technique. This is summarized in Figure 1 as Should, Can, Will and Did which are the key terms in the weekly work plan (Ballard, 2000). Should reflects the preferred priority, Can what is possible now given availability, Will the commitment and Did what was achieved and reported by percentage planned completed (PPC). Traditional practices do not consider a difference between what Should, Can, and Will be done, the assumption being that pushing more tasks will result in better results. The general idea is that in order to obtain an even workflow, a weekly work planning and a careful monitoring of the plan performance is needed. This takes place through the weekly plan, prepared on site and as close as possible to the week in question. The weekly plan defines what Will be done and PPC tells what Did get done.

Critical Chain Project Management

A central driver for adopting CCPM is enabling more predictable and shorter project lead times. The argument is that this not only will enhance time-related order-winning criteria but will also reduce cost and improve adherence to specification. The main conceptual elements and distinctive features of CCPM relate to planning, execution and improvement as detailed below (Goldratt, 2007).

Project planning

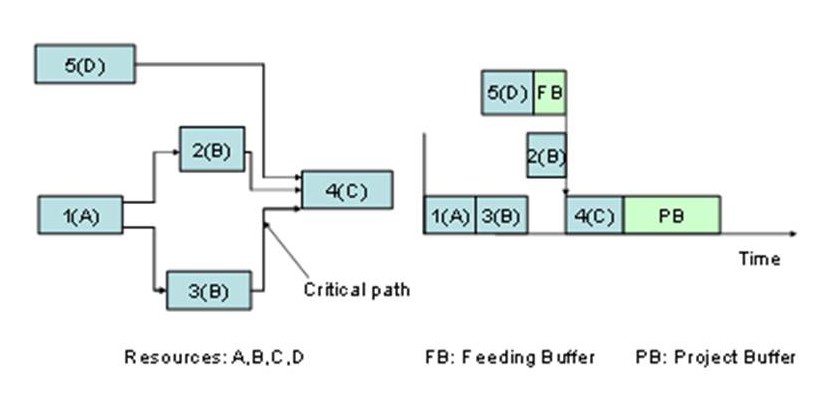

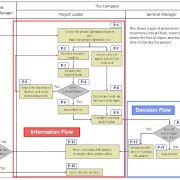

- CCPM takes account of resource as well as precedence dependencies in determining the project duration. This is termed the critical chain. In Figure 1, the critical path would be denoted by activities 1-3-4, whereas in CC it is denoted by 1-3-2-4 due to common resource B. In such cases, the critical chain is shown to be longer than the critical path and all four activities need to be managed accordingly.

Figure 2 Network diagram (left) and critical chain schedule showing buffers (right) (Stratton, 2009)

- CCPM introduces the concept of project and feeder time buffers to accommodate the effective management of buffer time that is commonly wasted at the activity level when managed locally. The project buffer is located at the end of the project to protect the critical chain, and feeder buffers isolate activity sequences with float from the critical chain (see Fig.2). Thus, such buffers enable aggregation of the buffer time as well as better control, enabling both shorter and more controllable lead times. In establishing these buffers, the proposed start point is to halve existing activity times and put half of the remainder into the aggregated buffer. Therefore, the buffer is equal to a third of the activity and buffer combination (see Fig.2 for illustration).

- When planning in a multi-project environment, CCPM advocates staggering the release of projects around a designated resource that acts as a drum. This is used to ensure flow and avoid too many open projects that result in excessive multi-tasking and missed due dates.

Project execution and continuous improvement

- Task completion reporting

It is common practice for activity times to be reported in terms of work done, an economic measure that is often only formally reported weekly or even monthly. With CCPM the remaining time to complete the activity is reported on a much more frequent basis – ideally daily.

- Provide visibility of upcoming tasks

As there are no intermediate task dates in the planning system the task-time-remaining data provides advanced notice of upcoming tasks (this has previously been referred to as a resource buffer).

- Current and upcoming tasks are monitored in line with priorities to ensure tasks are effectively progressing.

In the more complex multi-project environment, there are many in-progress tasks competing for a resource provider’s time. In CCPM they are prioritised in terms of the ratio of critical chain completion and buffer consumption, commonly using green, yellow and red priority colour codes. Upcoming tasks are also displayed, indicating their relative priority as well as the projected time when these tasks are expected to become available to that resource.

- Buffer consumption is monitored daily by the project manager and recovery action taken where necessary.

Consumption of the buffer indicates a task is exceeding the ambitious time and that the task manager may need assistance. Action at the project level may be needed to recover a situation.

- Senior managers monitor the status of all projects and take action where necessary.

At this level, the priority status of all projects is reviewed periodically to monitor and address higher level programme recovery.

- Reasons for delay are monitored and provide focus for improvement.

The relevant reasons for delay are extracted to focus improvement activity.

The planning and execution steps form the core of the CCPM approach but are not sufficient on their own. Pre planning steps involve reducing the number of live projects and ensuring that pre kitting is complete before a project is allowed to start.

What evidence is there to support the claims?

Objective support for the value of these two approaches can be both empirical and theoretical, as reported below.

Last Planner

The reported benefits, for all parties involved in construction projects, deriving from the implementation of Last Planner go beyond the initial theoretically justified benefits. These empirically observed benefits include: improved planning efficiency and reliability, improved productivity, improved plan reliability, more accurate prediction of resources, reduced uncertainty, preparation of team members to be in collaboration, enhanced learning process by continuous assessment, improved work quality and safety, and thereby reduced duration and cost of projects, promotion of other development work such as risk management, and facilitated implementation of organisational change and continuous improvement. These benefits are evident in many case studies reports and research papers across several countries (Ballard, 1994; Ballard and Howell, 2003; Kim and Jang (2005); Koskenvesa and Koskela, 2005; Mossman, 2007; Alsehaimi et al., 2009; Ballard and Howell, 1997; Koskenvesa and Koskela, 2005; Fiallo and Revelo, 2002; Ballard, 1999; Ballard et al., 1996; Junior et al., 1998; Thomassen et al., 2003).

Critical Chain Project Management

Case and survey research into the application of CCPM are still very limited. However, one measure of the level of interest in CCPM is the availability of CCPM-capable project management software. There is a growing range of software systems claiming to be CCPM-capable ranging upward in price from $250.

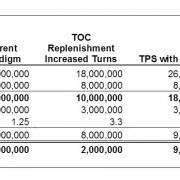

Realization the suppliers of the Concerto CCPM software has published customers’ case studies which include ABB, Delta, Boeing, US Marine Core Base, Lucent Technologies, Hewlett Packard and US Air Force Warner Robins Air Logistics Centre (Concerto Case Studies, 2010). Realisation has also been closely involved in the development of Goldratt’s (2007) Strategy & Tactic implementation guide, and the software is closely aligned with it. Using the Realisation Website (Concerto case studies, 2010) data, typical benefits include: reduced lead time by 25%; delivery performance increased to 90+%; and increased throughput by 20% with the same resource. Of these few have been formally published with one prominent exception, Warner Robins Air Logistics Centre (Srinivasan et al., 2007), where they implemented CCPM to reduce repair turnaround time on C-5 Galaxy transport aircraft.

In the construction sector, Stratton (2009) reported case research into a pilot implementation of CCPM using the strategy and tactics advocated by Goldartt (2007) in a multi project environment. This implementation was shown to follow the prescribed guidance with significant improvements in delivery performance and cost across 4 projects.

The use of CCPM on public works programmes in Japan since 2004 (Kishira & Ohara, 2005) has recently been expanded nationally through the Japanese government public works programme (Stratton, 2009) with reductions in duration averaging 20% and cost 7%.

CCPM has also been reviewed critically from a theoretical standpoint and the issues raised may be classified as follows.

- Originality – Numerous authors have acknowledge the approach (Newbold, 1998; Leach, 1999; Steyn, 2001, Herroelen, W. and Leus, R. 2001) but others question the originality. Trietsch (2005) is most critical in this area but does not question the contribution of the overall approach as does Raz et al. (2003).

- Oversimplification – Several authors (Raz et al., 2003; Elton and Roe, 1998) argue the approach brings more discipline but raise reservations over downplaying the traditional importance of personal project management skills.

- Paradigm change / over complication – Lechler et al. (2005) acknowledges the clear benefits but highlights the challenge in adopting a different mindset and suggests it could explain some failures. They suggest a CCPM-lite version that would not have feeder buffers (p56).

- Pipeline scheduling – Raz et al. (2003) question the stability of a bottleneck resource within a multi-project environment, as does Trietsch (2005). This is now acknowledged by Goldratt (2007) who now argues any limiting resource is likely to move, and the real issue in projects is not resource constraints but synchronization.

- Buffer sizing – The introduction of buffers is widely acknowledged as a positive step in providing a means of managing uncertainty. Several authors raise question over the sizing of buffers and it needs to be acknowledged that there is no scientific basis for the buffer sizing.

Summary

Both LP and CCPM have been used productively over many years by practitioners but the nature of the environment makes the gathering of empirical research evidence difficult. CCPM has drawn more academic interest because of its broader application to project management and clear challenge to established project management practice and underlying theory. In both cases the value of the approach is supported by theoretical argument.

How and why do these approaches theoretically relate?

The review of LP and CCPM has clarified how these distinct approaches can be related to both reducing and managing variation and uncertainty. As with lean and TOC manufacturing, LP emphasizes waste reduction and CCPM the management of variability and uncertainty. It is, however, interesting to note how CCPM was a natural extension of DBR as both use time buffers. Whereas, LP represents a more radical departure form lean manufacturing. This may be explained by considering the strategic needs across the operations spectrum from project to line and the respective emphasis of managing and reducing variability. This might explain why LP elements could not be readily transferred from lean manufacturing whereas CCPM is more of a natural extension of DBR.

Planning

A clear distinction in these two approaches is the planning scope between Last Planner and CCPM. As the name suggests LP looks ahead up to 6 weeks to indentify what Should be done and ‘made ready’ but the main focus is on the detailed day to day planning over one to two weeks where what Should be done is reconciled with what Can be done (Fig 1) in establishing commitments about what Will be done. The LP system does not significantly contribute to longer term planning, giving little guidance on how to structure the master and phased plans.

CCPM conversely, encompasses the overall project plan, but does not address the day to day detailed planning. It is interesting to note that the S&T guide (Goldratt, 2007: 5,13,1) stresses the importance of the task activities not being too small (ie greater than 2% of the project lead time). This is to facilitate the control process and acknowledges the need to devolve the detailed planning to local decision making.

CCPM now embraces multiple project planning and the ongoing development of the approach is clearly evident in that a virtual drum is now advocated as a basis for staggering projects (Goldratt, 2007:15,13,3).

Execution

A key measure in LP is the percentage planned activities completed and this is

dependent on reducing uncertainty and coordinating activities in completing what is agreed on a weekly basis. Where the Should activity cannot be completed, a less critical substitute activity is prepared to ensure the resource is not idle.

In CCPM the control focus is on the ratio of consumption of the project buffer to completion of the critical chain and, therefore, the emphasis is on timely completion, hence prioritizing the Should over the Can activities. Although there is no formalized weekly planning meeting as in LP, the expectation is that projected activity completion dates are reported on a daily basis, although twice a week is possibly more realistic (Stratton, 2009). This, therefore, informs all involved of the status, as well as the priority of different activites, together with the significance of any delay. This status is then used to expedite activities or escalate additional resource requirements as required.

Improvement

LP as with lean is geared towards reducing waste and the associated uncertainty. A key feature of the weekly meetings is collecting information on the reasons for not achieving planned completions and targeting improvement. Although this was not originally part of CCPM this capability has recently been incorporated in some CCPM software and is key feature of the CCPM guide.

What are the wider implications for construction and project management?

Both systems address the need to plan and control in a highly uncertain environment:

- LP though pragmatic and collaborative planning focusing on the immediate actions.

- CCPM developing more formalized means of managing the uncertainty at the aggregate planning rather than detailed planning level.

This paper has helped clarify that the lean and TOC philosophies compliment each other and need to be reflected in any flow management systems. It is clear that both LP and CCPM have evolved to encompass common elements as in the case of CCPM embracing ‘make ready’ and targeted improvement. Although these approaches have been used in construction management for many years there development appears to be largely independent and the authors there is much potential in exploring their integration.

Although flow theory is clearly applicable to construction management more structured research is needed to verify these benefits and practically integrate the associated management and reduction of variation and uncertainty.

Conclusion

Generally, the starting point of development has a dominant impact on the initial nature and scope of the two approaches: Last Planner and Critical Chain. The LP method was developed in a design science research manner, to alleviate the practical problems of construction teams (Koskela and Ballard, 2006), whereas CCPM originated from an attempt to rectify shortcomings in the Critical Path Method, extending the TOC manufacturing application of time buffering. Traditional project management, as in the Critical Path Method (CPM), is based on a transformation concept of production. In this concept, the basic unit of analysis, the task, is atemporal and mutually independent except precedence relationships. The CPM procedure then finds the best order and timing of these tasks. Both CCPM and LP subscribe to flow conceptualization, which addresses how work actually flows, in time, through different stages of the project. However, these two methods pick up different foci in flow: CC operates through aggregated buffers, whereas LP endeavours to reduce the cause of buffers: variability. It is clear some of these distinctions have already diluted as the approaches have evolved in the same direction.

References

Alsehaimi A., Tzortzopoulos P. and Koskela L. (2009). “Last Planner System: Experiences from Pilot implementation in the Middle East”, Proceedings of the 17th IGLC conference, Taipei, Taiwan, July.

Ballard, G. (1994), “The Last Planner”. Spring Conference of the Northern California Construction Institute, Monterey, CA, April 1994.

Ballard, G. and Howell, G. (1998). “Shielding Production: Essential Step in Production Control”, Journal of Construction Engineering and Management, Vol. 124, No1, pp. 11-17.

Ballard, G. (2000). “The Last Planner System of production control”, PhD thesis, University of Birmingham, Birmingham, UK.

Ballard, G., and Howell, G. (2003). “An update on Last Planner.” Proceedings of 11th IGLC Conference, Blacksburg, VA.

Ballard, G., Tommelein, L., Koskela, L. and Howell, G., 2002. “Lean Construction Tools and Techniques”, in Best, R., and De Valence, G (Eds): Design and Construction: Building in Value. Butterworth-Heinemann, Oxford, pp. 227-255.

Concerto case studies (http://www.realization.com/) (accessed 24th March 10)

Deming, W.E., 1982. Quality, Productivity and Competitive Position. Cambridge, MA: MIT Press.

Elton, J., Roe, J., 1998. “Bringing Discipline to Project Management”. Harvard Business Review, March-April, pp. 53-159.

Fiallo, C. and Revelo, V. (2002). “Applying LPS to a Construction Project: A Case Study in Quito, Equador”, Proceedings of the 10th IGLC Conference, Gramado, Brazil.

Fondahl, J., 1980. “Network Techniques for Project Planning, Scheduling and Control”, in: Frein, J. (Ed.), Handbook of Construction Management and Organisation, Van Nostrand Reinhold, NY, pp. 442-471.

Goldratt, E.M. (1990), The Haystack Syndrome: sifting information from a sea of data. North River Press, Cronton-on-Hudson, NY.

Goldratt, E.M., 1997. Critical Chain. North River Press, MA.

Goldratt, E.M., 2007. Viewer Notebook: The Goldratt Webcast Program on Project Management – the strategy and tactics tree for projects 4.7.1. Goldratt Group Publication.

Herroelen, W. and Leus, R. 2001. “On the merits and pitfalls of critical chain scheduling”, Journal of Operations Management, Vol. 19, pp. 559-577.

Hill, T., 1985. Manufacturing Strategy. London: Macmillan Education.

Hopp W.J., and Spearman, M.L., 2000. Factory Physics. 2nd Ed., Singapore: McGraw Hill.

Howell, G. (1999). “What is Lean Construction-1999”, Proceedings of 6th IGLC Conference, California, Berkeley, 26-28 July.

Junior, A., Scola, A., and Conte, A. (1998). “Last Planner as a Site Operations Tool”, Proceedings of the 6th IGLC Conference, Guaruja, Sao Paulo, Brazil.

Kim Y. and Jang J. (2005), “Case study: An application of Last Planner to heavy civil construction in Korea”, Proceedings of 13th IGLC conference, Sydney, Australia, July 2005.

Kishira, Y., and Ohara, S., 2005. “Implementation of P2M for Public Construction and Analysis of the Results”. Proceedings of PM FORUM, July/August.

Kostella, L and Ballard, G., 2006. “Should project management be based on theories of economics or production?” Building Research and Information , Vol. 34, No. 2, pp. 154-163.

Koskenvesa, A. and Koskela, L. (2005). “Introducing Last Planner: Finnish Experiences”, Proceedings do the CIB Symposium, Helsinki, Finland.

Leach, L.P., 1999. “Critical Chain Project Management Improves Project Performance”, Project Management Journal, June, pp. 39-51.

Lechler, T.G., Ronen, B., Stohr, E.A., 2005. “Critical Chain: A new project management paradigm or old wine in new bottles?”, Engineering Management Journal, Vol. 17, No.4, pp. 45-58.

LCI, 2001. Lean construction institute. http://www.leanconstruction.org/

Mossman A. (2007), An Introduction to Lean Construction and Last Planner, workshop manual, available at (http://www.leanconstruction.org/) (accessed 25th March 10)

Newbold, R.C., (1998). Project Management in the Fast Lane – applying the theory of constraints. St Lucie Press.

Ohno, T., (1988). The Toyota Production System; Beyond Large-Scale Production. Productivity Press, Portland, Origan.

Raz, T., Barnes, R., Dvir, D. (2003) “A Critical Look at Critical Chain Project Management”. Project Management Journal. Dec, pp. 24-32.

Skinner, W., (1974), “The Focused Factory”, Harvard Business Review, May-June, pp113-21.

Srinivasan, M.M., Best, W.D., and Chandrasekaran, S., (2007), “Warner Robins Air Logistics Centre Streamlines Aircraft Repair and Overhaul” Interfaces, Vol. 37, No. 1, pp. 7-21.

Steyn, H., (2000), “An Investigation into the Fundamentals of Critical Chain Project Scheduling”, International Journal of Project Management, Vol. 19, pp. 363-369.

Stratton, R., (2009). “Critical Chain Project Management – Theory and Practice”. Journal of Project Management and Systems Engineering, TOC Special Issue, Vol 4, pp. 149-173.

Thomassen, M., Sander, D., Barnes, K., and Nielsen, A. (2003), “Experience and results from implementing lean construction in a Large Danish contracting firm”, Proceedings of the 13th IGLC Conference, Virginia, USA.

Trietsch, D., (2005), “Why a Critical Path by Any Other Name Would Smell Less Sweet?” Project Management Journal, 36(1), 27-36.

Womack, J.P., Jones, D.T, and Roos, D., (1990), The Machine that Changed the World, Macmillan, NY.

All materials available on the TOCPA site are the intellectual property of their authors and cannot be reproduced in any other media and used for any purposes without the prior permission in writing of the authors.