Production Flow

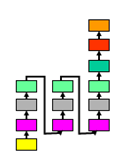

There are four basic types of work flows, which are referred to as “A”, “V”, “T”, and “I”.

Production processes differ by structure and the nature of flow of work-in-process through that structure. The flow of work through production has a direct impact on exploiting the constraint and subordinating non-constraints.

This taxonomy is based on the graphical representation of their respective flows.

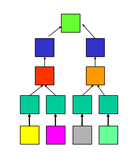

A-Flow typically begins with a larger number of raw materials that are combined as they proceed through production, ending in fewer number of finished products. Most “A” Flows are typically assembly operations.

Examples: Specialized equipment manufacturers, airplanes, large generators/ motors, consumer electronics, etc.

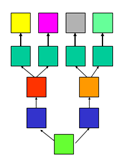

V-Flow typically begins with very few raw materials, sometimes even one. The flow of materials diverges as it proceeds through production, resulting in many more different kinds of finished products.

Examples: Basic industries like steel, Chemical processing, Paper production, Textile, Plastics, Wood products, etc.

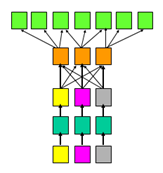

T-flow reflects a limited number of components that can be assembled in a wide variety of ways to create a very large number of finished products – far more than the number of original components.

The ending part of the process resembles “V” flow, the front part of it may resemble either “A” or “I” flows.

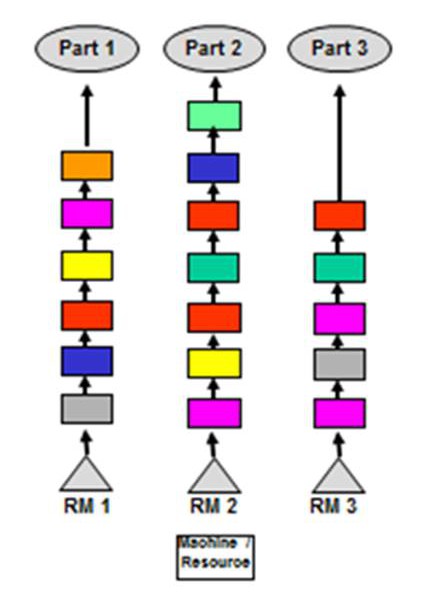

I-Flow typically begins with very few raw materials that proceed through production resulting in very few finished products.

I-plants are typically dedicated lines. Typically the line produces only a limited number of products, and it works on only one product at a time (flow lines).

Examples: Food and Chemical industries, Sheet-metal fabrication, etc.

OR

The production flow has a sequence of several operations repeating itself – the product goes through the same set of operations several times.

Source: Oded Cohen and Jelena Fedurko, Theory of Constraints Fundamentals, 2012