13th TOCPA International Conference, 19-22 May 2014, Muldersdrift, South Africa

SHARING EXPERIENCE

The 13th TOCPA International Conference and six TOCPA Master Classes took place in Johannesburg, South Africa on 19-22 May, 2014, in collaboration with TOCSA – TOC South Africa.

Program of the 13th TOCPA International Conference

Video and pdf materials from the 13th TOCPA International Conference

Photo from the 13th TOCPA International Conference

16 presentations were given by very experienced TOC practitioners on a wide spectrum of TOC applications. Below is the description of the conference presentations. The Master Classes were conducted by Philip Viljoen, Dr. Roy Stratton, Oded Cohen, Jelena Fedurko, Alenajdro Fernandez, and Henning du Preez.

South Africa has a long standing experience with TOC. A significant focus has been given through the years to the application of TOC for Mining. Several presentations give insight into the specific know-how of how TOC was a used in this area and the lessons learned. The other presentations cover a wide spectrum of TOC applications.

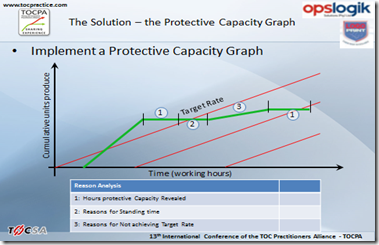

Protective capacity plays an important role in ensuring the high level performance of S-DBR. Yet, implementing this concept in reality is challenging. The presentation explains the problems facing the implementation and the direction that was taken in solving them. It also reveals what was not working well and the ideas how to improve the process working with the workers in implementing protective capacity.

Arrie van Niekerk– South Africa

Reflections on the origins of cost world local optima thinking in big corporate companies

Arrie presents his experience and his views about introducing TOC thinking into the conventional management within a company and within a conglomerate. The presentation contains some modeling of the impact of the balanced capacity approach versus the TOC thinking that promotes having a constraint resource in the flow. He demonstrates how the TOC system thinking can assist managers in large corporations that cannot see the alternative to the way they currently manage their systems. He presents practical direction as well as a vision for the strategic intent with the TOC initiative.

Dr Pieter Pretorius– South Africa

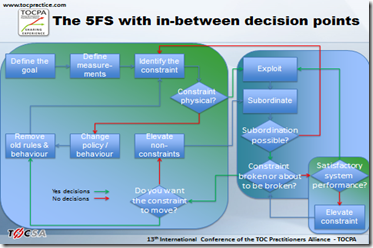

Introducing in-between decision points to TOC’s five focusing steps

The five steps of focusing are within the core principles of TOC. Pieter shares with us his work in further exploring important questions concerning these steps. He covers the question of the applicability of the steps to all types of constraints, and the extent that they are dealt with in a sequential way as suggested. There is the question of when we know and how do decide about moving from one step to the other and why we have to exploit before we elevate a constraint. The presentation also addresses the issue of where the constraint should be.

Dr Roy Stratton– UK

Applying TOC thinking to health and social care – theory and practice

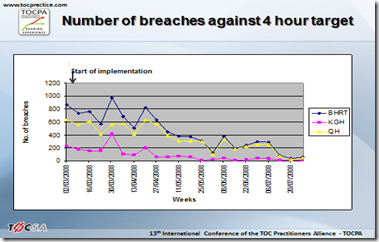

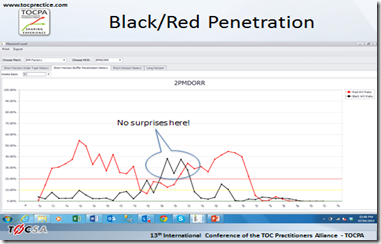

Roy presents the long standing and evolving application of TOC for the health and social care in the UK context. He describes how the 5 steps of focusing have been applied to the patient flow through the entire flow and the practical approach to the emergency and planned care management. The approach is a hybrid between SDBR, CCPM and Time Buffer Management. The presentation covers key important issues concerning the implementation of the approach. A case is shown on a specific district within the UK covering both community and social care, while sharing results and insights.

Dawid Janse van Rensburg– South Africa

Understanding and managing loading on the factory in order to ensure an agile supply chain and excellent due-date performance.

Dawid presents practical aspects of dealing with CCR within MTO Environment. TOC suggests using the concept of planned load of the resource with the highest demand that exceeds the standard quoted lead time (QLT). The presentation covers practical aspects of how to determine the load on the CCR, and how to use it in the process of promising delivery dates to the customers. David suggests getting the collaboration of the other functions to this method by introducing it into the S&OP. Several case studies are presented to demonstrate the approach.

Andy Anderson – South Africa

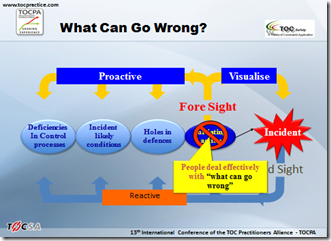

TOC and Safety

Andy presents an application of TOC for the area of Safety. Based on his experience, he has done the full Thinking Processes covering the UDEs and problems from the current reality, core cloud and direction of the solution. The direction suggests that people deal effectively with “What can go wrong”. As such they can analyze the anatomy of an incident. Identifying generic causes for incidents and addressing them lead to outstanding results in improving safety.

Jelena Fedurko – Estonia

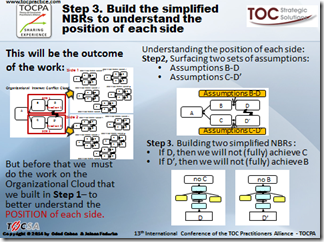

Using Clouds in making strategic decisions

Jelena takes us through an interesting and powerful use of the Thinking Processes for addressing the issue of making a strategic decision within the company in the case that the key players do not agree on which way the company should take. In a case that each player can block the decision, TOC can offer a systematic way to work with the parties to develop a way that will address the true concerns that the parties have regarding the suggested ways. The approach is an 11 steps process, with clear guidelines for each step. Jelena also brings clarity to the issue of the confusing claim that the cloud is built on the Necessity logic.

Malcolm Ferguson – South Africa

Strategy & Tactics – lessons from the field

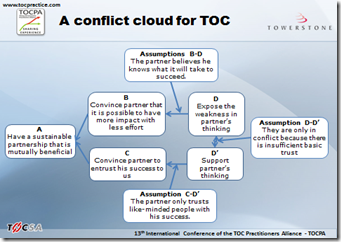

Malcolm shares the approach he uses when he facilitates organizations in the process of improvement and business feasibility. Malcolm’s facilitation philosophy centres on the concepts of interdependence and principled decision-making. An alignment journey begins with the question, “what is our measure of success?” Malcolm also suggests a cloud to present the conflict associated with introducing TOC.

Henning du Preez – South Africa

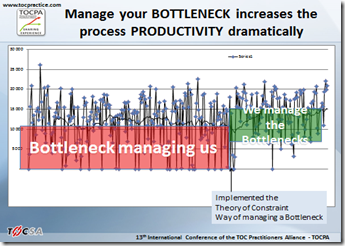

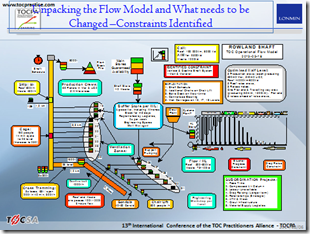

The Productivity Choice (A TOC application for Mining)

Based on the experience of implementing TOC in many mines Henning presents the phenomena that he calls “the 60% barrier”. The reality of mines that are managed in the conventional way is that whatever improvements management initiates the overall performance of the mine does not exceed 60% of its potential capacity. Henning suggests that the root cause for this barrier is that the bottleneck manages the system. By moving to actively manage the bottleneck there is a proven way to increase the level of utilization to 80%.

Dr Rudy Phillis– South Africa

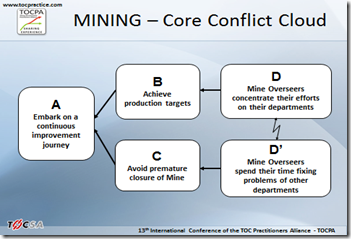

Mine Production Management – the core problem

Rudy shares his experience in bringing TOC to three major mining companies and the work that he has been doing in analyzing their reality with the desire to find the generic core problem of a mining company. For each one of these cases Rudy presents typical entities from their reality and suggests a core problem. He presents the manifestation of the core problem in different aspects of managing the company. Thereafter, he presents his views of how to go forward in the areas of operations management and leadership.

Arrie van Niekerk– South Africa

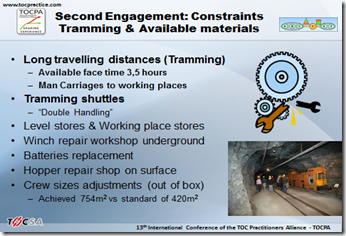

An eccentric practitioners story of 1.5 decades of TOC applications in the mining industry

Arrie presents a mosaic of several practical implementations of TOC in Mining Operations. Over the years, a repetitive pattern evolved and this story strives to portray that picture. It is a story of phenomenal results and achievements by some daring and dedicated role players in some of the most challenging working environments in South Africa. Arrie shares practical examples of solutions that were invented during the implementation and the impact they brought as well as some important lessons learned.

Katlego Mabote– South Africa

TOC and Authentic Leadership – Journey towards Excellence

In his presentation, Katlego looks into the leadership and leaders’ behaviour through the prism of “What to change” leading to “What to change to” and covers three areas: authentic leadership journey; TOC approach to change; and profit and sustainable behaviors. The presentation pinpoints current behaviours in an organisation that need to be changed and gives vivid examples of the impact of the current thinking model on the performance results versus the performance level after implementing TOC. Katlego also presents a template of a TOC dashboard for daily management.

Alejandro Fernandez– Colombia

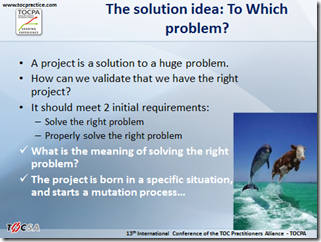

How to ensure that the project properly solves the right problem

Alejandro discusses an important issue related to managing project the CCPM way. While CCPM provides the project organization with the way to professionally manage project there is the question: Is the project the right one? He deals with the criteria and process for ensuring that the project will answer the needs of the system and bring value.

Johan Steyn– South Africa

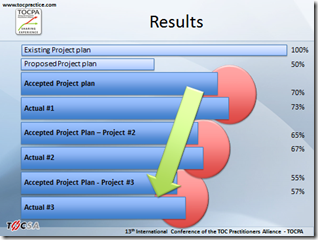

Critical Chain Project Management says 50%, but what is reality?

The CCPM solution challenges the time estimation of the duration of tasks within the project plan. As such there is a general recommendation to cut by 50% the time estimation for the individual task. Johan challenges the choice of the figure of 50% as a standard rule by bringing in examples from his experience in which 50% cut was too much or too little and suggests his views about how to handle the issue of cutting estimated task duration.

Philip Viljoen– South Africa

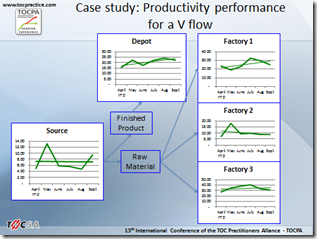

Throughput thinking and Performance Management

Philip discusses the issue of having the right measurements to support Throughput thinking and lead the company in the right direction. He brings practical examples of the measurements that were put in place to support management in decision making that increases Throughput more than Operating Expenses. The metrics deal with the global performance as well as the local performance of units within the flow.

Oded Cohen– Israel

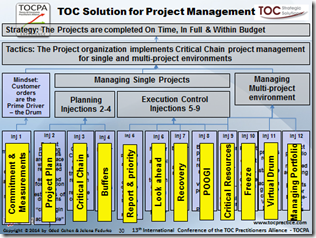

Special issues in implementing Critical Chain Project Management

Oded discusses different characteristics of six different CCPM implementations. Some of them have been successful and some not. He points out key factors that determine success or failure and suggests ways how to handle key reservations, questions and concerns that impact the quality of the implementation. In the last part of the presentation Oded summarizes the CCPM solution by Injections.

All materials available on the TOCPA site are the intellectual property of their authors and cannot be reproduced in any other media and used for any purposes without the prior permission in writing of the authors.

Leave a Reply

Want to join the discussion?Feel free to contribute!