16th TOCPA International Conference, 21-23 April 2015, Muldersdrift, South Africa

SHARING EXPERIENCE

The 16th TOCPA International Conference and four TOCPA Master Classes were held in conjunction with TOC Southern Africa.

Video and pdf materials from the 16th TOCPA Interntional Conference

Photos from the 16th TOCPA International Conference

10 presentations were given by experienced TOC practitioners on a wide spectrum of TOC applications.

South Africa has a long standing experience with TOC. This conference brings additional cases and experiences. The ten presentations cover: production, project management, supply chain, procurement, managing mines and views on selling TOC. Each one of these presentations adds to the growing collection of the shared know-how of TOCPA on the way to turn TOC solutions into reality.

Below is the description of all the conference presentations.

Opening : Welcome to the 16th TOCPA Conference, the third in South Africa

by Philip Viljoen, Oded Cohen and Jelena Fedurko

Dawid Janse van Rensburg

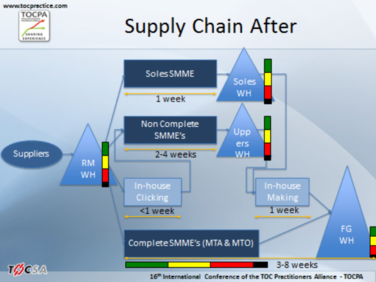

Driving SMME behaviour through a TOC priority system – Case Study of the Footwear Manufacturing Supply Chain at Watson Shoes

Dawid describes the challenges that the shoe manufacturers in South Africa have been facing due to the fierce competition due to the abundance that was created by importers – especially from China. It became apparent that make to order with long lead times was not acceptable anymore. The solution used – Make to Availability for the high-runners together with faster and more reliable MTO and some imports. As always – there are “Yes, Buts…”

Christo Wentzel

The road to TOC

Christo describes the early steps of implementing TOC in his company. This is an engineering environment with a lot of new product development. Projects, surprise-surprise, suffered from all the traditional symptoms and UDEs. Nevertheless, they have experienced the immediate improvements in performance after implementing CCPM. During the presentation Christo demonstrated managerial responsibility by generating positive variation to compensate for penetration to the buffer caused by the previous task.

Jelena Fedurko

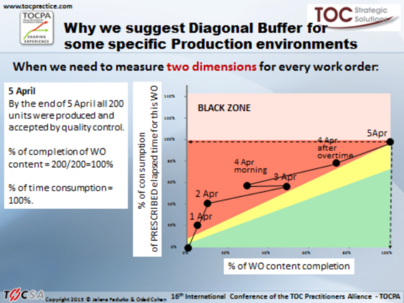

Using diagonal buffer for better managerial decisions in production and operations

Jelena restates the true meaning of Buffers in TOC and the significance of using them for managing the flow – in planning and in controlling the execution. While dealing with time buffers Jelena explores the situations in which a single dimension of the buffer – just the time – is not enough. In cases such as processes with high touch time or with sporadic variations in work orders the experience shows that the “Red Zone” of 1/3 of the time is not sufficient for recovery. Hence – the second dimension is introduced to indicate how close or remote the Work Order is to completion.

Katlego Mabote

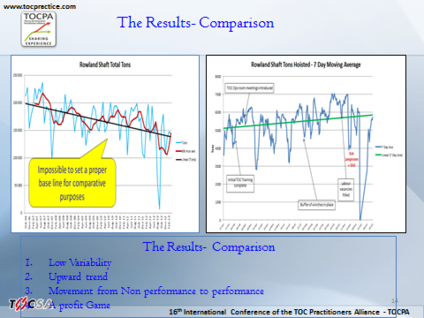

The Critical Conflicts of Efficiency measurements and TOC in Mining

Katlego takes us on his continued journey to bring TOC to the mines he works in. He argues that there are three different views when trying to identify the bottlenecks: there is the flow model, the management’s view and the supervisors’ view. These views differ from each other but nevertheless needed to be considered in order to get significant results.

Katlego presents some of the conflicts that block or slow down the implementation. He presents experience of handling these conflicts and the results they have been achieving. He has a strong conviction that the key to the proper implementation is setting up the right measurements.

Albert van der Wat, Kobus Snyman, Brian Ingram

Two cases on TOC Driven Procurement – Sharing the implementation and results at two SA implementations

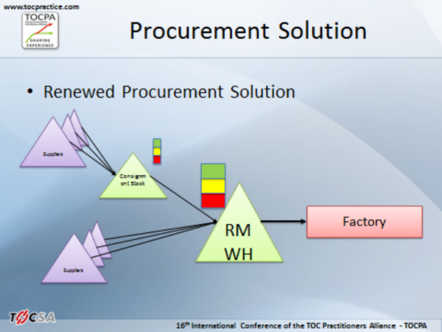

The presentation starts with Albert van der Wat discussing the conceptual use of the TOC solution for replenishment for procurement. He covers the challenges with long procurement time items as well as spare parts. He suggests how to improve the KPIs for procurement and presents the importance and the mechanism of DBM – Dynamic Buffer Management.

He then gives the floor to two companies to share their experience in using TOC for procurement.

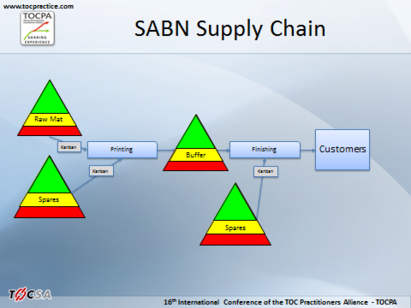

Kobus Snyman continues the presentation to share the implementation of TOC Driven procurement and results at a printing company.

They manage about 6000 SKUs using the TOC replenishment solution with DBM. They have managed to deal with the long lead time items through getting the buy-in of the vendors to look daily into their buffers. Remarkable results have been achieved in a short period of time.

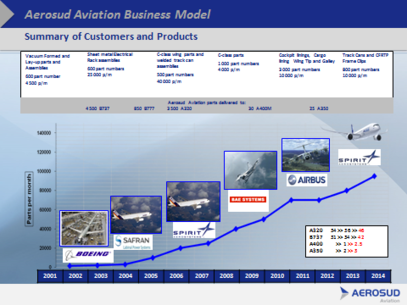

The presentation of TOC Driven Procurement is continued by Brian Ingram who shares the implementation and results at an aviation company.

Brain covers the growing challenge in supplying their products to the aircraft manufacturers as well as spare parts for airplanes in service. Their procurement deals with 3500 SKUs bought from 580 suppliers from the US, Europe and the UK. Procurement has to deal with average lead time is 90 days with some items that can go as high as 12 months. Many SKUs have limited life and many are high cost. The implementation of the TOC solutions supports management focusing on Reliability!

Oded Cohen

Leadership needed – the importance of daily measurement for setting the direction of the TOC Solution

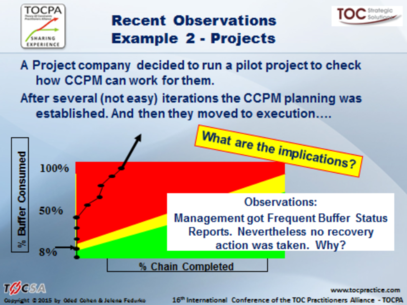

Oded takes us through the critical importance of leadership in the TOC implementations. Every solution is driven by the unique direction based on the TOC Way of Management. Demonstrating leadership is simple and practical and can be easily achieved through the use of the Daily Reports. Every TOC solution includes daily reporting on the status of the buffers and the key measurements. Top management should check daily the adherence to the objectives of the system and must prompt recovery actions when the signals from the buffers are Red or Black presenting a threat to achieving the objectives of the system.

Loubser de Kock

DBR production implementation in long touch time environment

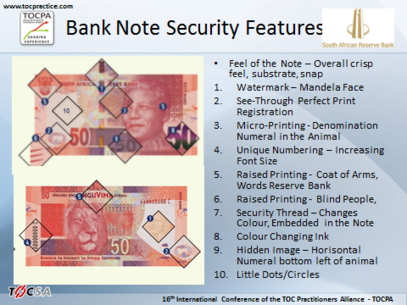

What can be better than that: printing money!

Loubser is taking us through the experience of implementing TOC in managing the production of bank notes. Even though there are only five different products, and only one customer (at the moment) there are a plenty of challenges to managing the flow. Currently the production is managed as MTO. However, the objective of management is to provide outstanding service to their customer and to release capacity to entice other governments to print their money with them. For that the company needs to move to MTA while using internal supply chain buffers to overcome the long lead time forced by the technological processes.

Barry Urban

To sell a counter intuitive product you need to use counter intuitive selling techniques

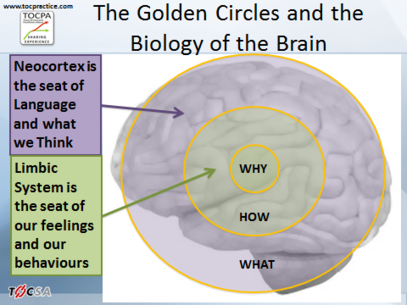

Barry shares his views on the difficulties of selling TOC.

He brings into the discussion the dominance of the emotional part of the human brain in decision making. As TOC is logical all the TOC practitioners appeal to the ratio of the potential buyers of TOC. However, as most people tend to make emotional decision this approach is not that successful. Barry suggests to use the Limbic map and to engage a new practical approach to selling TOC.

Jaco Laubscher

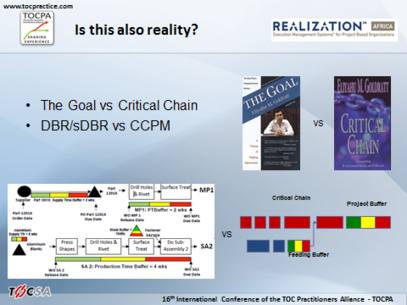

Production environment vs Project environment, do they really exist?

Jaco shares with us his views regarding what he consider as the artificial split between production and project management environments. He brings the similarities between these two areas. Based on his experience of working with many companies he claims that there are very few environments that can be considered as pure production or pure project management. The reality is that there are many mixed environments of production with some elements of project management or projects with production parts that behave like projects. Jaco concludes with the suggestion to capture the way TOC practitioners adapt the solution of either production or project management with elements from the other TOC solution.

Andy Anderson

Implementing Critical Chain Project Management at a power station

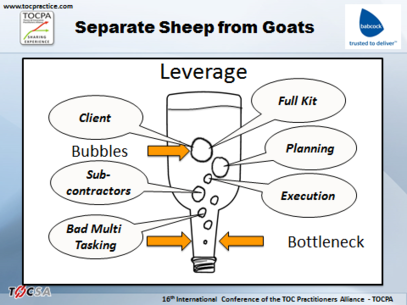

Andy presents on behalf of the company Babcock. He shares their experience in implementing CCPM in an area that the country (and many other countries) has a major need: to get more electricity! The company builds and repairs boilers for power stations. Time to complete is the name of the game. The company has set up the objective to be reliable – to be acknowledged for being remarkably good at meeting their promises. To achieve their objective the company introduced a new mind-set, established new rules, reduced bad multi-tasking, involved the right people in the planning, and so on. The results are remarkable.

Philip Viljoen

Closing the 16th International TOCPA Conference

Philips summarizes the conference with a quick review of the presentations.

Thanks to all participants, presenters, Nicholas Renecle and Sondia Viljoen (behind the camera).

All materials available on the TOCPA site are the intellectual property of their authors and cannot be reproduced in any other media and used for any purposes without the prior permission in writing of the authors.