19th TOCPA International Conference, 18-20 June 2015, Bogota, Colombia

19th TOCPA International Conference and TOCPA Master Classes were held in Bogota, Colombia on the 18-20 June, 2015, sponsored by Piensalo Colombia and TOC Strategic Solutions.

Pdf materials from the 19th TOCPA International Conference

Photos from the 19th TOCPA International Conference

This was another significant event of sharing experience among TOC practitioners that have been implementing TOC solutions and methodologies in variety of organizations and circumstances.

Like in all previous TOCPA conferences – each presentation brought additional facet and practicalities of the HOW to implement and adds to the overall practical know-how of the TOC Practitioners community around the world.

DESCRIPTION OF THE CONFERENCE MASTER CLASSES AND PRESENTATIONS

Oded Cohen, TOCPA Co-President

Master Class – Lessons learnt in implementing MTO

The master class covered 10 major lessons learned in implementing the TOC solution for production in many companies around the world:

1. TOC Solution for MTO Works!!!

2. The critical importance of the Buffers

3. The role of Operations/Production

4. Planning in MTO

5. Managing Purchasing for MTO

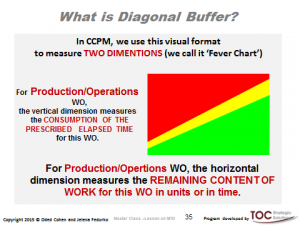

6. The Diagonal Buffer

7. Handling special cases

8. The critical importance of Leadership

9. The custodian of the knowledge

10. Teaching MTO

Alejandro Fernandez, Principle of Piénsalo Colombia

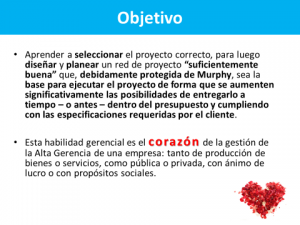

How to properly select the right Project?

In his presentation Alejandro deals with the issue of how to choose which project to choose. He claims that management should ensure that the new project addresses the system’s constraint through checking that it follows steps 2, 3 or 4 of the five focusing steps.

• Exploit the constraint, or

• Subordinate everything else to the decision to exploit the constraint, or

• Elevate the constraint.

If the Project complies with one of these conditions, the Project will increase the Throughput generated by the system.

If the solution – the Project – has few significant positive effects and many negative effects, the Project has no merit.

José Cedeño, PMO Manager and Mercedes Alcívar, Accountant Chief, La Fabril, Ecuador

LA FABRIL- The Experience of implementing TOC

Jose and Mercedes describe the process of implementing TOC throughout the years. The presentation includes video testimonials from the managers of Marketing, Purchase, Production, Logistics and closing the General Manager.

After the first 3 months they already experienced results:

- the local distribution warehouse had a 30% inventory reduction (“Now we have room for playing football in the warehouse”),

- the customer level service rose from 60% to 90%+.

With these results they rolled out the implementation at a national level and in all the plant warehouses.

3 years ago La Fabril implemented Buffer Management in major distributors. Today they have 90 clients in Quito and their goal is to reach 400 clients at national level.

Jelena Fedurko, TOCPA Co-President

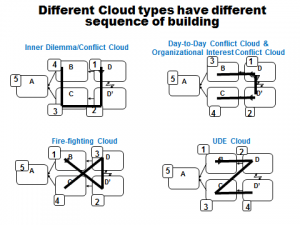

Master Class – TOC Thinking Processes: Clouds wording, UDEs and UDE Clouds, how to get them right?

Jelena presents how to improve our skills to build better clouds, especially the Undesirable Effect Cloud with the objective of getting the Consolidated Cloud. The issues presented:

- A structured process and purpose of working with UDEs and UDE Clouds

- How to recognize the points in the process of thinking that one should be conscious to check that their thinking will not lead to unhelpful conclusions.

- The 10 rules for wording UDEs

- The sequence to construct each individual UDE Cloud in such a way that it will manifest its respective UDE and be logically sound

- Difficulties in determining the content of box B

- The common mistake of a mirror reflection between an UDE and boxes B and/or D

- Difficulties in wording C as a system’s Need

- Rules to consolidate UDE Clouds to identify a more generic Cloud

- Building assumptions – for which UDE clouds, when to build and for what purposes.

Adriana Gómez, TOC Manager at Prodesa

Experience implementing TOC in PRODESA S.A

Adriana presents how Prodesa – a home construction Company have achieved 92% on time delivery of their projects – Within Budget and Specifications and On Time. She shares how they have managed to put on one small piece of paper the current state of all the projects and the management priorities. This paper has supported management while controlling the projects flow.

Her main conclusions:

- It is possible to successfully implement TOC in construction companies.

- The full support of the CEO determines the success of the implementation process.

- Results are not immediate, but the cultural change is achieved in short time.

- The consensus must be first, nothing must be imposed.

- The first achievement is to have the real information about the current state of the Projects.

- The Schedule must reflect reality of what is happening in the construction site.

- Project networks must be revised and optimized every year.

- Reports must be designed and adjusted to the needs of management of each area; the success is that the reports are useful.

Alfonso Navarro, TOC Consultant

Developing Decisive Competitve Advantages with TOC in the Supply Chain of a big Company: AUTECO CASE

Alfonso describes the TOC implementation process in one Colombian company, leader in motorcycles production. This is a typical implementation of Make to Availability ensuring high level of service to the downstream chain and to the dealers.

Alejandro Cespedes, CEO of Simple Solutions

The experience of developing TOC Software

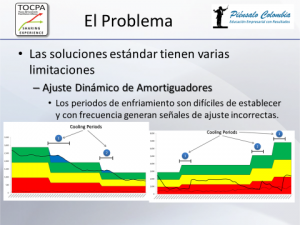

Alejandro explains the challenges in developing and selling TOC software. The standard solutions have several limitations:

- Buffer Dynamic Adjustment

- If a buffer stays “too long” in red, the buffer is increased.

- If a buffer stays “too long” in green, the buffer is reduced.

- The instruction to wait a prudent time after the adjustment to keep tracking.

Besides offering alternatives for these limitations, other improved solutions were mentioned, like:

- Priorities for stock buffers.

- Rope violations.

- Purchase priorities calculations.

- Planned Load.

Rafael Conde, from Expertos TOC

A fast view of my life with TOC

Rafael has been long time with TOC. He presented his TOC experiences.

He focuses on the viable vision and the conditions to achieve meaningful sustainable improvement.

He covers building the decisive competitive edge and the results achieved by deveral companies.

Roberto Novoa, CIPLAS Production Manager

The experience of implementing TOC in CIPLAS – A Viable Vision Project

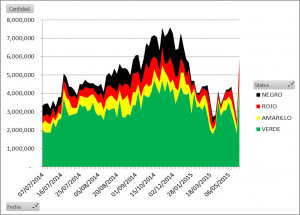

Roberto describes the implementation of the viable Vision project in his Company, emphasizing the significant reduction of MTO orders in black, 5 months after starting the implementation.

DDP has had complex periods, black orders were in critical levels as well as red orders. They had to make a plant daily meeting for each process and coordination meetings to find causes for the delays and to find solutions to solve problems. Now managers chase reds ASAP. Each area with delays knows – every day at first hour – the problems that are under their influence and that they need to come with the solutions. Planning is using homemade tools adapted to QAD (The IT System). The recent results motivate the company to move on to a real buffer management!

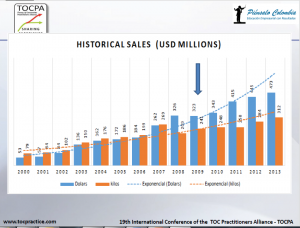

Mario Hernández, General Manager of Dulces La Bugueña

The experience of implementing TOC in LA BUGUEÑA

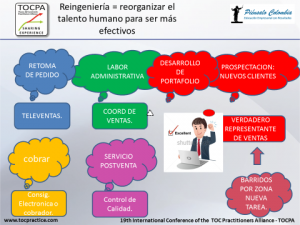

Mario describes the 15 years voyage with TOC, in operations, finance, logistic and sales. Currently the company is implementing the Sales Re engineering concepts of Justin Roff Marsch, that in the pilot test have generated the following results:

- 15% sales increase in 2 months en two zones in Bogota (pilots).

- 23% sales increase in Villavicencio.

- Easier work control.

- Better task execution based on expertise.

- Truth moments increase from 1 to 15 (the moment in which you can increase sales face to face with the client).

- 30% conversion rate success (sales process face to face).

Andrés Cisneros, Plasticaucho Industrial Corporate Manager

The experience of implementing TOC in Plasticaucho

Andres shares his experiences implementing TOC. The presentation includes videos from the managers of Logistic, Production, Finance, IT (their experience integrating SAP with TOC in the ERP), and the CEO.

The Company has a measurement of selling 0.75 shoe pairs per second, for a total of 25 million shoes per year. Currently they are working on the following “Yes, But..”:

- The same reference produced in 2 countries: how to calculate the buffer?

- Accommodating minimum batches in production.

- How to be prepared in advance to seasonal demand (raining seasons, school classes start).

- Budget is a tool for making decisions for medium and long term.

- Policies for increase and reduce buffers.

- Increase the Raw Material purchase order frequency, which increases the product cost.

- Lead time definition

Alejandro de Francisco, Plastilene Line Manager

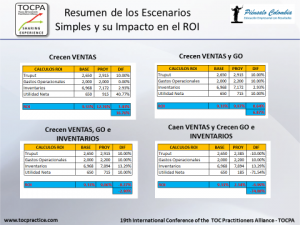

How to make Management Decisions thinking in ROI

Alejandro shared his insights about the use of ROI for the decision process by top management. ROI is a composed measurement with big management power. The critical importance of the ROI requires ensuring the proper model for calculation as well as all the relevant data and variables for the calculation.

ROI measurement requires the understanding that some relevant management decisions must be visible and updated, as they have influence in the 3 key operational measurements: T, I and OE. At the same time Alejandro argues that management should not miss some derivate measurements, like:

• Inventory turns.

• Planned Load on Productive resources.

• Throughput per unit of the CCR.

• Over expenses – significant changes of OE due to variability.

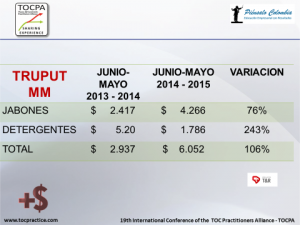

César Cendales and Leticia Garcia from T&R Group

TOC Implementation – T&R Group

Cesar and Leticia share details of a holistic TOC implementation in a Colombian consumer goods company producing soap and detergents – Jabonería El Tigre. The main elements of the solution implemented were:

- Viable Vision definition.

- Design and structure of a commercial expansion plan.

- Redefinition of sales, marketing, logistic, finance structure.

- Update information system.

- Adapt a Brand and Product launch and renovation methodology.

- New Price strategy and commercial conditions.

- Launch new brands, products and portfolio renovation.

- Opening new markets

- Structure sales process for buying to third parts.

Some of the main results:

- Positive market perception regarding the un-refusable offer on time delivery.

- Increase productivity of internal processes and reduced their lead times.

- New product launch projects reduced from 2 years to 8 months (using CCPM).

- TOC have supported us developing a clear and simple methodology for running the company and their markets

Eliana Marcela Peña, Teacher at Escuela de Estudios Industriales y Empresariales, Universidad Industrial de Santander

Experience in teaching Critical Chain – CCPM

Eliana shares her experiences teaching critical chain, where she faced two main problems: companies demanded the use of PMI for Project management, and it is not easy to have access to proper CCPM software. Oded Cohen suggested the use for teaching purposes CC-mpulse the software Tony Rizzo and his colleagues donated to the management community. The software is available on the internet as an open code (for Ms-Projects 2007 and below). Currently, Eliana is in the process of persuading the university to use Exepron ® for all the Post-graduated programs UIS is offering at national level.

All materials available on the TOCPA site are the intellectual property of their authors and cannot be reproduced in any other media and used for any purposes without the prior permission in writing of the authors.